Guard Hardener® WO: one product, two functions:

1. Hardens/consolidates and crystallises

Guard Hardener® WO is a product for consolidating inorganic, porous, poorly cohesive materials. It can also be used for restoring old monuments, fountains, cornices, and statuary in natural stone.

Guard Hardener® WO remedies the principal causes of deterioration of materials such as freeze/thaw cycles and acid rain, damage due to salts (crystallisation, hydration and hygroscopy), expansion and contraction of the material, modification of the structure of limestone carbonate under the action of CO2-containing water, colonisation by cryptogamic agents (moss, lichen etc.), use of excessively alkaline cleaners and/or failure to rinse cleaners off...

Guard Hardener® WO recreates the mineral crystalline network destroyed by one of the causes mentioned above, so that the treated substrate is reverted to its original mechanical properties.

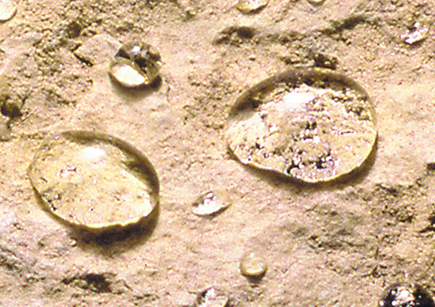

2. Water- and oil-repellent

Guard Hardener® WO also has water- and oil-repellent properties that provide lasting protection for all porous materials against penetration by water, oil and stains of all kinds.

Guard Hardener® WO slows the aging of substrates, facilitates their maintenance and prevents the main causes of deterioration such as pollution, grease, soiling, water intrusion, moss, etc.

.jpg)

.png)

.jpg)